- First ever 3-strand slab casting concept for achieving higher capacity while keeping the same space used for casting at the steel plant

- Investment will significantly increase production capacity

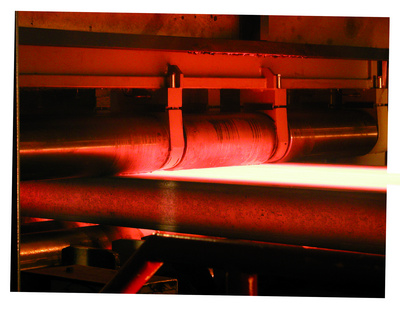

Recently, Chinese steel producer Tangshan Donghua Iron and Steel Enterprise Group placed an order with Primetals Technologies to supply a new 3-strand continuous slab caster for its plant in Tangshan, Hebei province, China. The machine will supply slabs to a recently installed hot rolled rolling mill. Start-up is expected for December 2022.

Unique design

This caster will feature a unique design of the segment roller drives and the protective shields for the middle strand. It is the first ever 3-strand slab casting solution. Tangshan Donghua will benefit from a higher capacity compared to employing a 2-strand slab caster – at lower space requirements in comparison with the installation of an extra caster.

The 3-strand slab caster will be equipped with the latest casting technology. Straight cassette-type Smart Moulds ensure optimized primary solidification of the strand. The DynaWidth mold-width adjustment system is used for flexible and fast slab-width changes. The DynaFlex hydraulic oscillator flexibly adjusts the mould-oscillation parameters, resulting in improved strand-surface quality of the slabs. The secondary cooling features DynaJet spray cooling with a centre/margin setting for an even more precise cooling of the slab edges, which reduces corner cracks when casting advanced steel grades.

Sophisticated casting automation solutions

In addition, the 3-strand caster will be delivered with a sophisticated automation package. DynaPhase, Dynacs 3D, and DynaGap Soft Reduction 3D are dynamic secondary cooling and soft-reduction packages that significantly contribute to quality improvements during the continuous casting process by taking into account thermodynamic effects such as shrinkage and phase transitions. LevCon is a system for automatic mould-level control, with “autostart” casting functions and auto-adaptive dynamic bulging compensation. Mould Expert helps to prevent caster-mould breakouts and digitally monitors the mould in real time.

Wide business scope

Established in 2009, Tangshan Donghua’s wide scope includes sintering, ironmaking, steelmaking, and bar and high-end wire rod rolling. As a business open to new technologies geared toward increasing their domestic footprint in steel production, Tangshan Donghua has found a valuable partner in Primetals Technologies. Since 2017, Primetals Technologies provides Donghua with metallurgical services and offline maintenance for their continuous casting machines.

Key facts: 3-strand slab caster

Radius: 8 meters

Metallurgical length: 40 meters

Thickness of slabs: 210 millimetres

Width range of slabs: 750 to 1,100 millimetres

Casting speed: up to 2.5 meters per minute

Key facts: Expert systems implemented at Donghua’s slab caster

Several expert systems will be implemented at this slab caster:

Nozzle Expert checks the condition of the secondary cooling system and detects any clogged nozzles and leakages with high accuracy.

Quality Expert tracks, controls, and supervises quality related data and quality prediction for the cast products.

Speed Expert calculates the optimal casting speed in any casting situation while considering factors like superheat and heat pacing.

Yield Expert is a cut length optimization system which considers scrap portions, quality defects, weight restrictions, and width changes in order to minimize scrap and optimize yield.